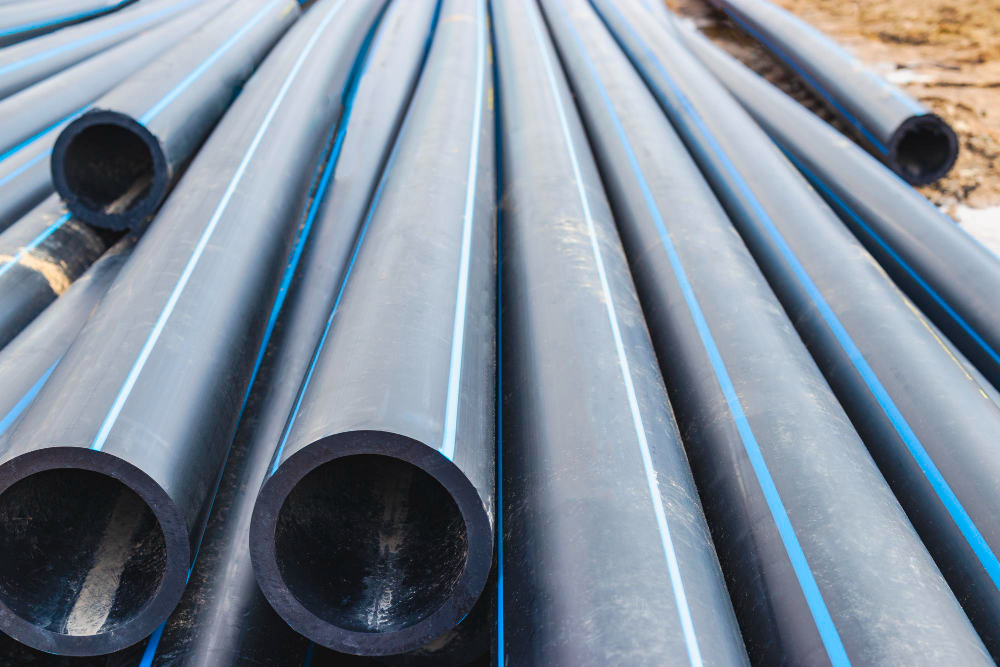

HDPE Pipes: The Smart Choice for Modern Engineering

- RAIPIPE

- July 11, 2025

- No Comments

High-Density Polyethylene (HDPE) pipes are widely recognized for their strength, durability, and versatility, making them a preferred choice across numerous industries. Manufactured from high-density polyethylene, a thermoplastic polymer, these pipes combine lightweight properties with exceptional robustness. Their unique characteristics make them suitable for critical applications such as water supply, gas distribution, sewage, and drainage systems.

Unlike conventional materials like steel or concrete, HDPE pipes offer superior resistance to chemicals and environmental stressors, ensuring longevity and reliability. Additionally, their non-toxic nature and recyclability contribute significantly to environmental sustainability.

Key Advantages of HDPE Pipes

The popularity of HDPE pipes stems from several notable benefits:

- Long-lasting Durability: These pipes typically have a lifespan exceeding 50 years with minimal upkeep. They can tolerate extreme temperatures and resist physical damage such as cracking or breaking.

- Flexibility: Their ability to bend without cracking allows these pipes to adapt to shifting ground conditions or uneven terrain, reducing the risk of damage.

- Corrosion Resistance: Unlike metal pipes, they do not rust or corrode, even when buried underground or submerged underwater, making them ideal for harsh environments.

- Cost Efficiency: The production and installation costs of these pipes are relatively low, which makes them economically attractive for large-scale infrastructure projects.

- Eco-Friendly: They are fully recyclable and have a smaller carbon footprint compared to traditional piping materials, supporting sustainable construction practices.

- Leak-Free Joints: These can be joined using heat fusion, creating seamless, leak-proof connections that enhance system reliability and reduce maintenance needs

Common Uses of HDPE Pipes

Thanks to their versatile properties, HDPE pipes are employed in a range of sectors:

- Water Distribution: They are extensively used for clean water supply systems. Their resistance to corrosion, ultraviolet rays, and chemicals ensures a reliable and long-lasting water transport solution. Their flexibility also helps maintain integrity despite ground movement.

- Sewage and Wastewater: In wastewater management, HDPE pipes are favored for their leak resistance and chemical durability, which help maintain efficient and safe sewage transport.

- Gas Pipelines: The gas industry relies on these pipes for natural gas distribution because they resist the corrosive effects of gases and are easy to install and join, even over long distances.

- Agricultural Irrigation: They are commonly used in irrigation systems due to their flexibility and resilience against environmental factors, ensuring consistent water delivery to crops.

- Industrial Applications: HDPE pipes are widely used in industries for transporting chemicals, slurries, and gases, thanks to their high chemical resistance and ability to withstand high pressures and impacts

Why Opt for HDPE Pipes in Your Projects?

Choosing HDPE pipes for your next project offers several compelling advantages:

Their durability and flexibility ensure a long service life and adaptability to various environmental conditions.

They provide a cost-effective solution without compromising quality or performance.

HDPE pipes contribute to environmental sustainability by being completely recyclable and reducing carbon emissions during production and installation.

Their wide range of applications makes them suitable for infrastructure, agricultural, and industrial uses.

Conclusion: A Smart Investment for Reliable Infrastructure

HDPE pipes offer a powerful combination of strength, flexibility, corrosion resistance, and leak-free joints, making them ideal for both short- and long-term projects across various industries. Their durability and ability to withstand environmental stresses ensure reliable performance, while their recyclability and low carbon footprint support sustainability goals.

You can contact RAI Pipes, the best HDPE pipe manufacturer, to explore high-quality options tailored for your projects.

By consulting with the best HDPE pipe manufacturer, you can choose a piping solution that’s perfectly tailored to your specific needs—ensuring efficiency, cost-effectiveness, and environmental sustainability. Partnering with the best HDPE pipe manufacturer means investing in a future-ready system that offers long-term value and supports modern green building standards.