Cost Benefits of HDPE Pipe: 7 Amazing Ways to Save in the Long Run

- RAIPIPE

- September 9, 2025

- No Comments

Introduction – Why Cost Benefits of HDPE Pipe Matter

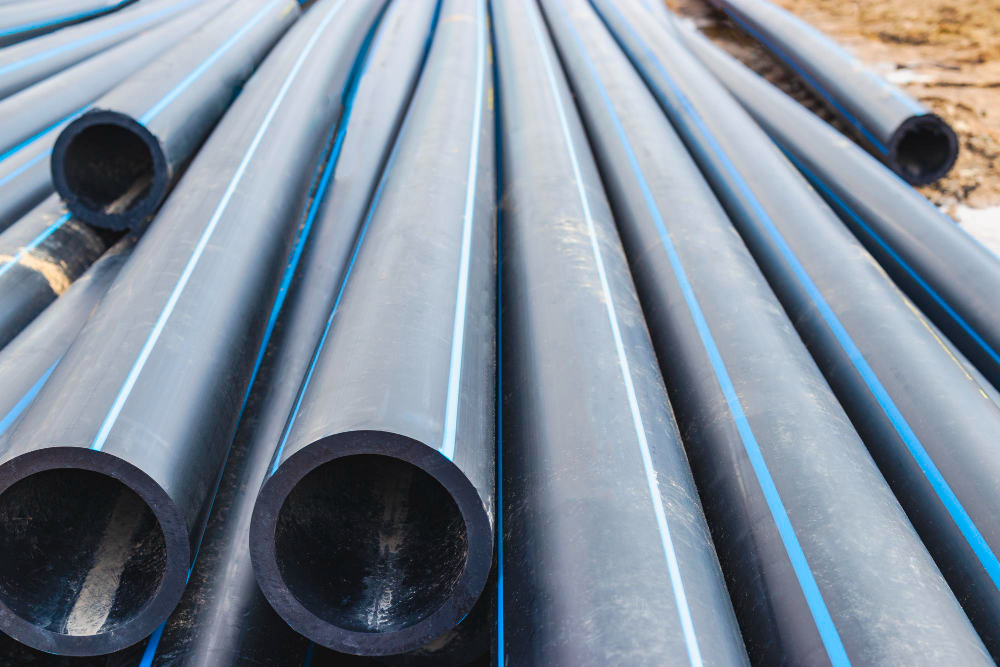

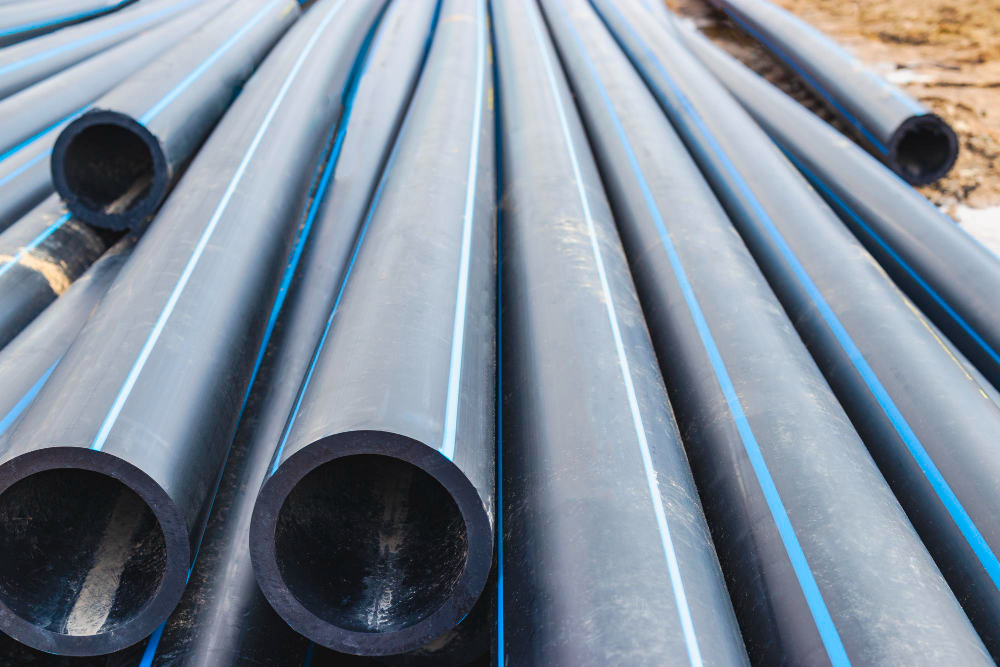

Every infrastructure project—whether water supply, gas distribution, or industrial fluid transfer—comes with high financial commitments. Decision-makers often focus on upfront material costs without fully considering how the chosen piping system will perform in the long run. This narrow perspective can lead to higher unplanned expenses due to frequent repairs, higher energy consumption, or early replacement. High-Density Polyethylene (HDPE) pipes are increasingly recognized as the smarter choice for both immediate efficiency and lifetime value. By analyzing the cost benefits of HDPE pipe, stakeholders can see the bigger picture: faster installations, fewer failures, lower operational requirements, and significantly improved return on investment.

Unlike traditional pipes such as steel, ductile iron, or concrete, HDPE pipes combine strength with flexibility, ensuring durability even in challenging environments. They are engineered to resist corrosion, chemical damage, and ground movement stresses that often compromise older materials. As a result, long-term projects in sectors like water utilities, mining, agriculture, and municipal infrastructure are shifting toward HDPE. In this expanded guide, we’ll break down the top seven financial advantages of HDPE that make it a forward-looking choice for smart businesses and governments.

Top 7 Cost Benefits of HDPE Pipe

When considering the economic side of infrastructure projects, understanding the cost benefits of HDPE (High-Density Polyethylene) pipes is essential. In this section, we will discuss the top 7 ways in which HDPE pipes offer significant financial advantages over traditional piping materials. From reduced installation and maintenance costs to increased durability and longer service life, these factors collectively help lower total expenditures for both contractors and utility providers.

Lower Installation Costs: One of the Biggest Cost Benefits of HDPE Pipe

Installation is often the most expensive phase of any piping project, sometimes contributing to nearly 50% of the total expenditure. HDPE pipes significantly cut these costs because they are lightweight and easy to transport, even in large diameters. Unlike steel or concrete pipes, which require cranes or specialized heavy equipment, HDPE can often be moved and placed by smaller crews using simpler tools. This reduces logistics costs as well as labor expenses.

Additionally, HDPE uses fusion-welding techniques to create continuous, leak-free pipelines without the need for heavy jointing materials or bulky connecting parts. This saves both time and money during installation. Contractors benefit from shorter project timelines, and municipalities reduce expenses linked to road closures or public disruptions during pipe-laying activities. Ultimately, lower installation costs set the stage for more savings throughout the pipeline’s entire service life.

Reduced Maintenance Expenses Over Time

With infrastructure, maintenance is often the silent budget-drain. Traditional metal pipes corrode, requiring coatings and continuous inspections. Concrete pipes deteriorate when exposed to aggressive soils or chemicals, leading to frequent intervention. HDPE, however, resists both corrosion and wear. Its flexible nature also prevents crack formation from soil shifts or external stress.

Operators experience fewer emergency repairs, which reduces downtime costs as well as the expense of sending crews into the field. Since HDPE joints are virtually leak-proof, concerns about water seepage and surface damage are minimized. Over decades of service, these reduced maintenance demands highlight the cost benefits of HDPE Pipe, translating into millions of dollars saved for municipalities and industries alike. More importantly, the predictability of HDPE’s maintenance requirements allows for better budget control in the long run

Long Service Life (50+ Years) Adds to Overall Savings

One of the most striking cost-saving advantages of HDPE is its incredible service life—often more than 50 years. Many case studies across the globe show HDPE pipelines serving communities for generations without needing significant rehabilitation. In contrast, steel pipes often last about 20–30 years, while some concrete systems begin to fail earlier under aggressive conditions.

What makes HDPE last so long? Its resistance to environmental stress cracking, fatigue, and chemical damage means it does not deteriorate in the same way traditional pipes do. This longevity reduces the frequency of pipe replacement projects, which are both costly and disruptive. By choosing HDPE, organizations secure infrastructure that will serve reliably for half a century or more, ensuring that the initial investment spreads out over a much longer period—greatly improving cost efficiency.

Resistance to Corrosion and Chemicals Ensures Durability

Corrosion and chemical degradation are among the most common reasons for premature pipe failure. In industrial facilities, agricultural networks, and municipal sewage systems, exposure to harsh fluids and aggressive soils accelerates wear on traditional pipes. Steel rusts, concrete erodes, and even some plastics lose structural integrity. HDPE, however, is non-reactive and specially designed to withstand a broad range of environmental challenges.

From acidic soils to saline water conditions, HDPE remains unaffected. Its smooth surface prevents scaling and residue build-up, which extends not only its life but also system efficiency. When corrosion is not an issue, operators avoid the costly practices of lining, coating, or cathodic protection required by other materials. This natural resistance clearly demonstrates the cost benefits of HDPE Pipe, as it provides long-lasting reliability and minimizes both expected and hidden costs.

Fewer Leakage Issues = Lower Water Loss and Extra Savings

Water loss due to pipe leakage is a global issue—utilities can lose up to 30% of treated water before it reaches consumers. This “non-revenue water” results in massive economic waste, higher pumping costs, and greater environmental strain. HDPE pipes directly address this problem with their fusion-welded joints that create a monolithic, leak-free system.

Unlike PVC or metal pipelines, where fittings and joints can fail over time, HDPE’s seamless structure ensures much tighter security against leaks. Over decades, this results in billions of liters of water being saved, which not only reduces costs but also improves sustainability—an increasingly important factor in modern infrastructure planning. Less leakage directly translates into reduced operational bills and stronger resilience during water scarcity.

Energy Efficiency in Water Flow Cuts Operational Costs

Pumping water or other fluids through rough, friction-heavy pipes requires more power. Traditional materials like cast iron naturally have rough inner surfaces that increase energy demand in order to maintain constant flow rates. HDPE, on the other hand, features an extremely smooth bore that significantly reduces friction losses.

Over years of operation, this lower energy requirement leads to massive utility savings. In fact, energy expenditures for pumping can account for nearly 25–40% of the total operational budget in large water utilities. By simply switching to HDPE, systems can operate at far lower energy consumption levels, making them both more economical and environmentally responsible. This efficiency, when calculated over decades, contributes directly to a lower overall lifecycle cost for HDPE compared to alternatives.

Better ROI Compared to Traditional Pipe Materials

When evaluating any capital investment, return on investment (ROI) is the most important metric. HDPE consistently beats traditional materials by combining low installation costs, minimal maintenance, fewer losses, and extended service life. While the initial purchase price may be comparable—or slightly higher in some cases—the total lifecycle cost invariably ends up much lower.

Cities, industrial plants, and agricultural projects that adopt HDPE often report recovering their investment much faster because expensive repairs, downtime, and replacements are minimized. Beyond the direct financial benefits, HDPE ensures smoother operations, reduced energy use, and lower environmental impact. Altogether, these factors create superior ROI compared to traditional pipe systems, making HDPE the financially sound choice.

Conclusion

The long-term financial implications of any infrastructure project depend heavily on the materials used. HDPE pipes provide clear advantages at every stage of use—from installation and maintenance to operational efficiency and durability. By preventing leaks, reducing energy demands, resisting corrosion, and delivering service life beyond 50 years, HDPE proves itself as a reliable, cost-effective material for critical pipelines.

Ultimately, the cost benefits of HDPE pipe go beyond saving money—they also represent sustainability, resilience, and smarter financial planning. For businesses, municipalities, and industries looking to future-proof investments, HDPE pipe isn’t just an alternative; it’s the most strategic choice available.

You can also read: HDPE Pipes: The Smart Choice for Modern Engineering